Capture Design Intent while Increasing Efficiency

Visible Edge professionals capture design intent and automate the creation of standard and pseudo-standard designs creating models and documentation.

Visible Edge has taken our customers Engineered-to-Order (ETO) products and built automated, customized engineering systems that enables them to quickly configure and design their products while improving their quality and delivery times. These applications can be used to quickly generate a potentially infinite number of accurate 3D solid parametric models along with all the desired documentation such as drawings, BOM’s, flat patterns, CL files. These applications can also be used to run a quick structural/thermal/vibration and thermo-fluid analysis to verify the designs capability to meet minimum specifications. The models are also used to create proposals, estimates, and other documents in a fraction of the original time.

The ultimate sales tool that can be used in front of or even by your customer directly! Whether driven by a sales person or from a web site by the customer, our applications allow your customers to interactively design, visualize and verify designs to their specifications while reducing the sales cycle time for you. Built-in design rules and constraints ensure form, fit, function and manufacturability while allowing for a potentially infinite number of design scenarios. Virtualize your On-Line Catalog with flexible and “visible” parts and assemblies.

What is Automation?

- For company management it is capturing, protecting and leveraging your Intellectual Property (IP). Leveraging this programmed IP allows for the quick communication of design rules to the next generation of engineers and designers. Productivity gains of 10:1 are typical.

- For the engineers and designers it is about freeing your minds to explore numerous ideas, optimizing those ideas and proving their viability. This flexibility can be achieved while automatically maintaining the consistent application of design rules. These rules can be easily applied to the design of families of parts and assemblies. Automation of repetitive tasks frees your mind to explore and innovate.

- For sales people it is about increasing sales by reducing sales cycles and engineering and design costs while giving the customers exactly what they want. It allows for the quick generation of accurate sales proposals and quotes.

- For manufacturing it is about accurate, enhanced and complete documentation that eliminates waste and shortens production learning curves.

- For your customer it is about receiving maximum value from their investment.

| Basic Premise |

| |

Create a solid model then apply logical and mathematical formulas to the models that control how it can be manipulated. Solid models can be combined into assemblies with logical and mathematical formulas being applied at the assembly level. A top down design approach can also be taken. Applications can be as simple as automatically modifying the thickness of a washer as its diameter is increased. There is virtually no limit to the designs rules that can be captured in the models. Minimum deliverables include but are not limited to:

|

| |

- 3D parametric solid models and assemblies

- 2D assembly and detail drawings

- Machine files (CNC)

|

- Sheet Metal Flat Patterns

- Analysis documentation (FEA)

- Bills of materials (BOMs)

|

| |

|

| Other Benefits by Department |

| |

|

Management |

Sales |

Engineering |

Manufacturing |

|

Profitability

Market share

Communications

Corporate image

Revenue stream

Lead times

Capture of IP

Resource efficiency

|

Quoting time

Quoting accuracy

Quoting capabilities

Sales cycle

Sales coverage

Deal volume

Marketability (Web) |

R&D time

Cost & Quality

Cycle times

Accuracy &

Optimization

Configurability

Documentation time

Staff skill utilization

Capture of IP |

CNC integration

Shop modifications

Scrap reduction

Rework reduction

Error reduction

Training reduction

Drawing Comprehension

|

|

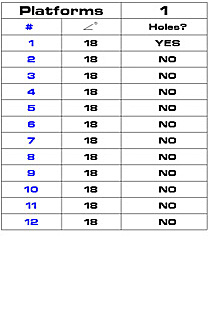

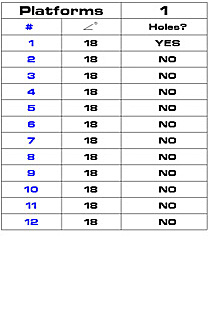

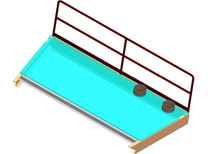

Platform Configuration Example

|